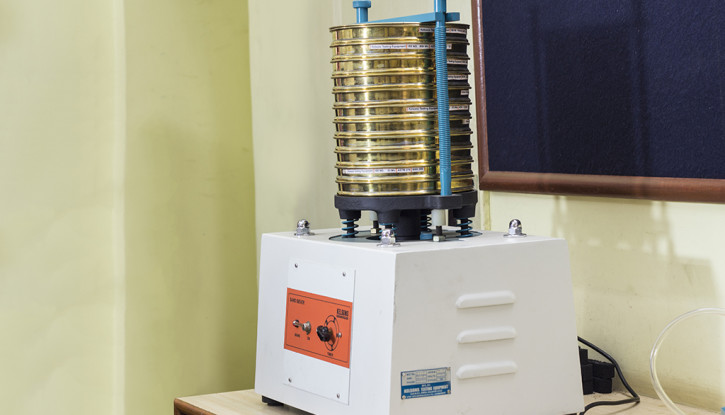

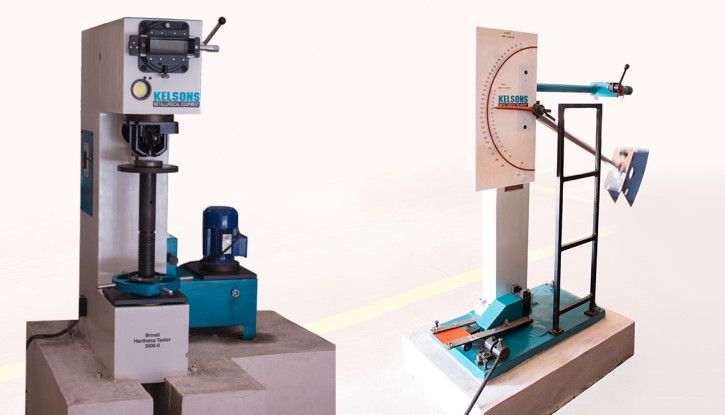

Our castings are produced to meet the highly demanding operational requirements of our customers. These are then chemically and mechanically tested. The surface quality of the casting is confirmed by either Magnetic Particle or Dye Penetrant testing. Internal soundness is checked by radiographic (X-ray) or Ultrasonic testing. Non Destructive Testing (NDT) is carried out through out the process. In order to assure the highest quality products, we utilize a sand testing lab with cutting-edge testing equipment, such as mold hardness testers, sand clay washers, rapid moisture testers, core hardness testers, sand rammers, and compatibility meters, sand sieve shakers, permeability meters and a green compression strength machine.