At our modern “No Bake” manufacturing plant, we produce a wide range of graded cast iron & alloy steel castings. A completely automated process allows us to offer a high degree of flexibility in quality, quantity and delivery lead times.

At our modern “No Bake” manufacturing plant, we produce a wide range of graded cast iron & alloy steel castings. A completely automated process allows us to offer a high degree of flexibility in quality, quantity and delivery lead times.

Installed 175 KW/1000 Hz induction furnace with internal water circulating system, which allows for a clean, energy-efficient and well-controlled melting process. The furnace, with a capacity ranging from 300 to 500 kg.consistsof a non-conductive crucible fitted with a hydraulic tilting mechanism.

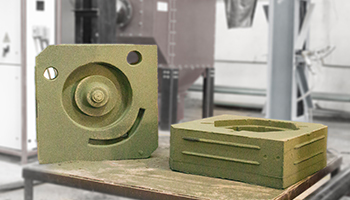

No Bake is one of the most efficient casting methods currently available. No bake molding, unlike green sand molding,box-less molding, and shell sand molding, is well known for it’s quality, versatility, low rejection rates and thus the most economically viable method today to produce quality castings in volumes. It offers good dimensional tolerances and reduces gas related defects.