Technical

SG Iron is also known as Ductile Cast Iron, Nodular Cast Iron, Spheroidal Graphite Iron and Spherulitic Cast Iron. As the name Ductile Iron suggests this grade of Cast Iron has a degree of ductility.

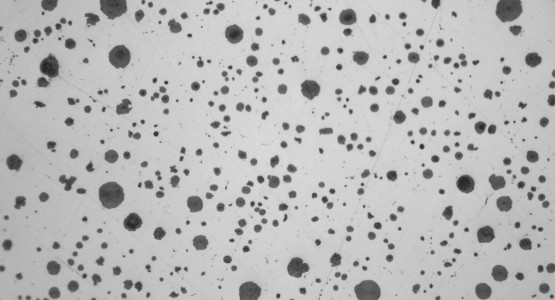

This nodular graphite structure inhibits the creation of linear cracks hence the ability to withstand distortion .The main characteristic of this material is the structure of the graphite. In SG Cast Iron the graphite is in the form of spherical nodules (hence the name Spheroidal Graphite) rather than flakes as in Grey Iron..

As with Grey Iron, there are many grades of SG Iron that can be specified offering to industries with varying degrees of tensile strength and elongation. The various grades are achieved through a combination of alloy additions and heat treatment.